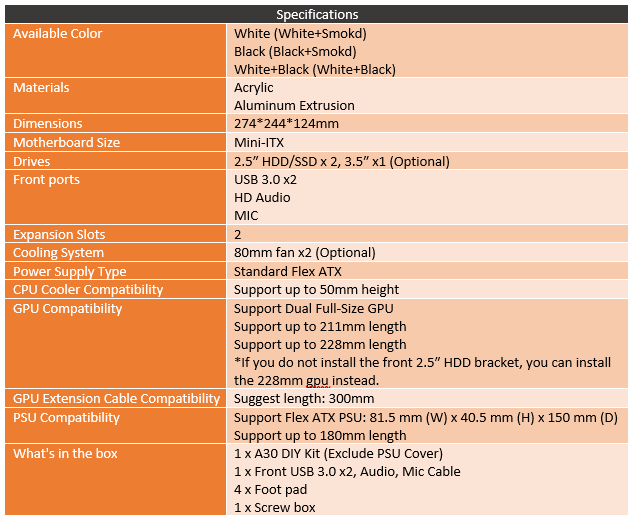

I hope by now most of you have figured out that I love SFF builds. Over the years we have built a new Lunchbox build with the goal of going smaller and building an even more capable gaming rig to take to LANs. So I am always on the lookout for new and different cases that might fit the bill. Well, early this year I came across a company called GEEEK that has a few small ITX cases including one that really caught my eye that used a FlexATX power supply to save space. That was the A30 and GEEEK was nice enough to send one over to check out. With a unique extrusion based construction they were able to keep the costs down. With a budget-friendly price and an acrylic construction, Its looks good. But is it easy to build and how does it all perform when together? That is what I want to find out today.

Product Name: GEEEK A30

Review Sample Provided by: GEEEK

Written by: Wes Compton

Pictures by: Wes Compton

Amazon Affiliate Link: HERE

Packaging and Assembly

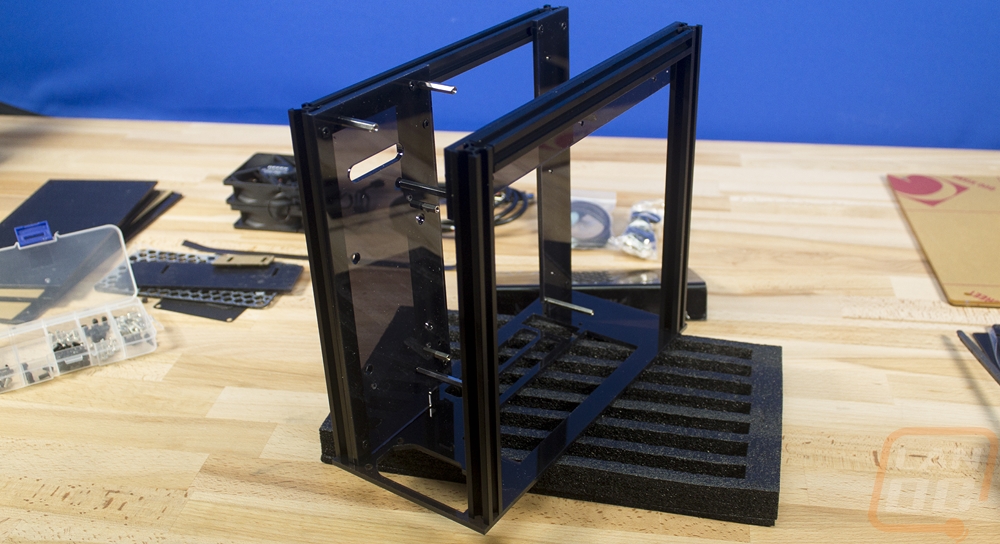

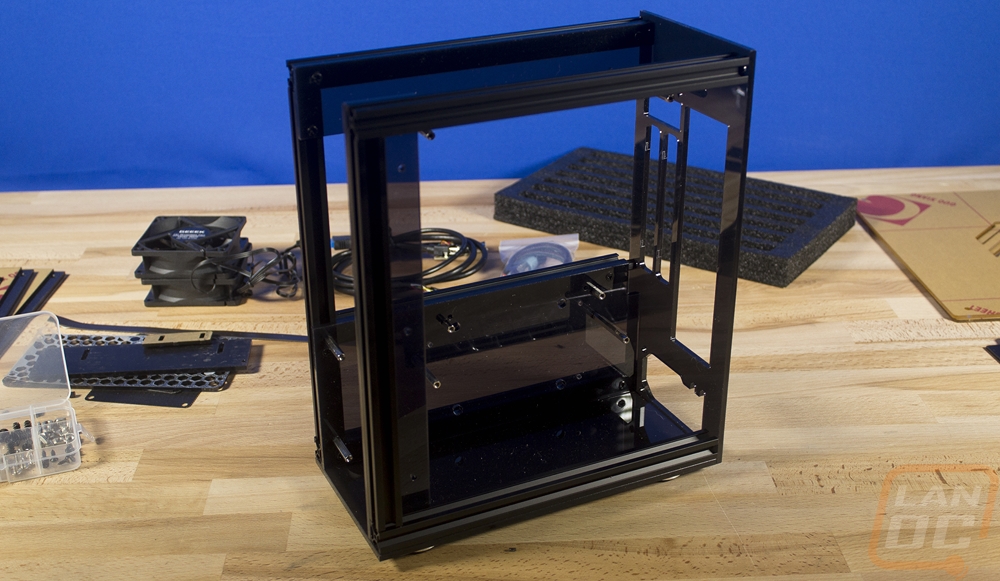

Okay, so one of the quirks of the A30 is that it comes flat packed. This isn’t the first case that I have had come this way, Case Labs does the same thing on some of their models. But the A30 is a little different, this case uses an aluminum extrusion frame. So this isn’t a simple attach the panels together. This is a lot closer to building some of our 3d printers. GEEEK even warned me ahead of that that this is flat packed and that it is an acrylic and extrusion construction. I suspect some members of the media are turned off from building their own case, but longtime readers will know I LOVE building things like keyboards from scratch, our 3d printers, and all of the 3d projects. If anything I end up loving things I have built more. So the flat packed box with GEEEK on the side wasn’t a turnoff, it was more of a challenge or an adventure waiting to happen.

So inside the box, the PCIe riser (that is sold separately) came right up on top. Below that was a foam tray with slots carved into it for each of the aluminum extrusions and then another box. Up under the box and foam were all of the acrylic panels. The largest ones are on the bottom with foam in the corners to protect them. Then the rest were all wrapped up together to keep them from moving around. All of the smaller panels also have a plastic on them and the two side panels have a paper attached. Both will be peeled off to build, my fingernails aren’t looking forward to it.

So the box that was inside of the box has basically anything that isn’t main structure inside of it. This includes the two fans and fan filters that are add-ons. The large PSU cover is also an add-on as well. Of interest though is the small plastic tray that comes with all of the screws, standoffs, and other mounting hardware. There is also a standard vandal LED switch for the power button, it has a black sleeved cable. And the front panel I/O with its two USB 3.0 connections and HD Audio. This has a PCB with the GEEEK branding on it and both cables are covered in black rubber. The audio does still have the colored cables visible at the end of the cable though.

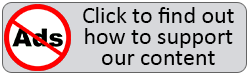

So with all of the components out and sorted through I could start building. I got the hardware tray out and kept that close and I used my phone to pull up the online building instructions. I would normally use a laptop but I didn’t really have the extra space in my work area. So this is where I ran into some confusion, the GEEEK website has two sets of build instructions labeled 1.1 and 1.0 but I don’t know what version our kit is. There is also a 1.2 listed currently that doesn’t have its own instructions as well. But no worries I can figure it out (I hope). I started off with our first panel, the bottom half of the motherboard backplate.

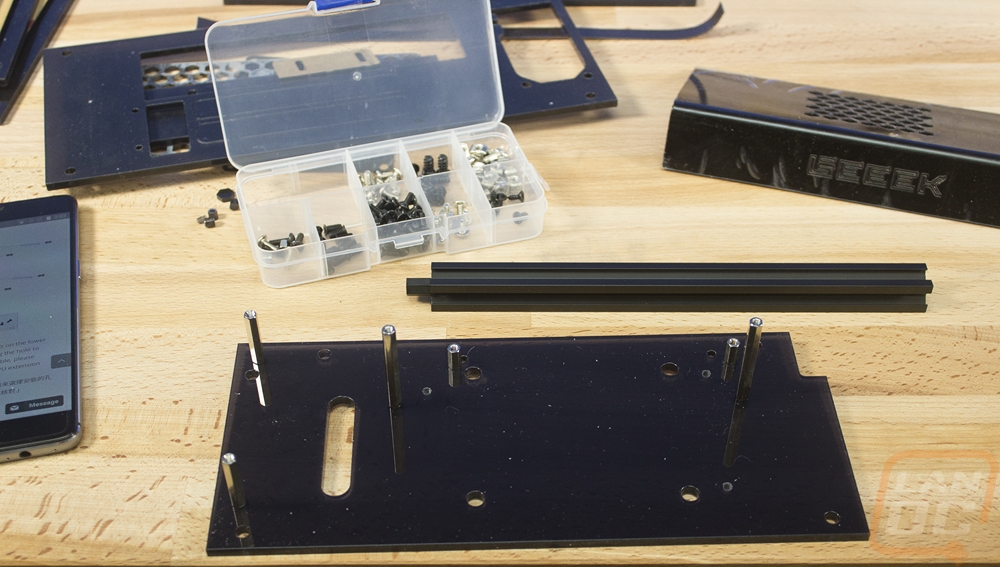

The next steps had me putting that panel as well as a second panel together with four different extrusions. It is really important that you take a look at the separate instructions with tips on connecting these extrusions. Getting the clamps locked into place wasn’t exactly the most fun, I think GEEEK could take a few tips from the 3d printing communities designs that have t-slots that fill the entire extrusion. The included t-slot bolts work but like to spin around when you are tightening them. Anyhow this section I found myself doing a few times when one clamp would spin, even when together it is all a little loose until the whole case gets together so be careful.

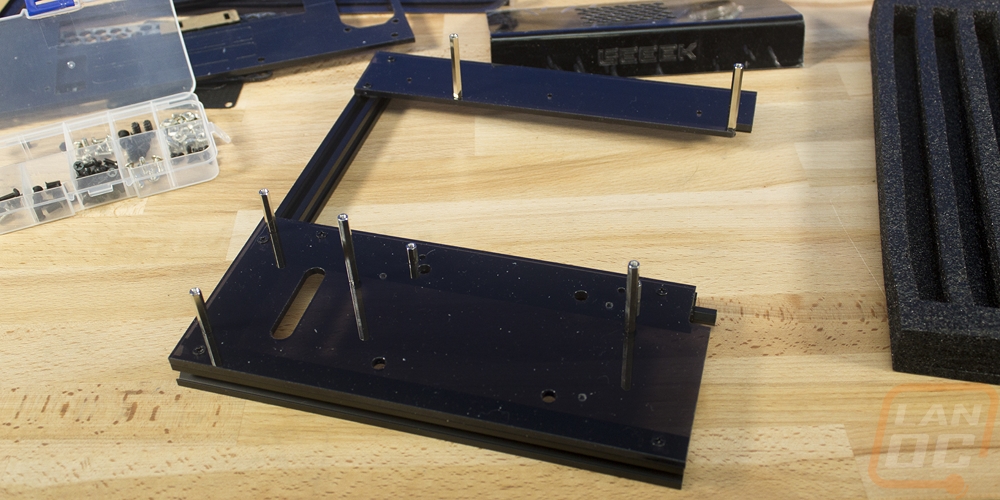

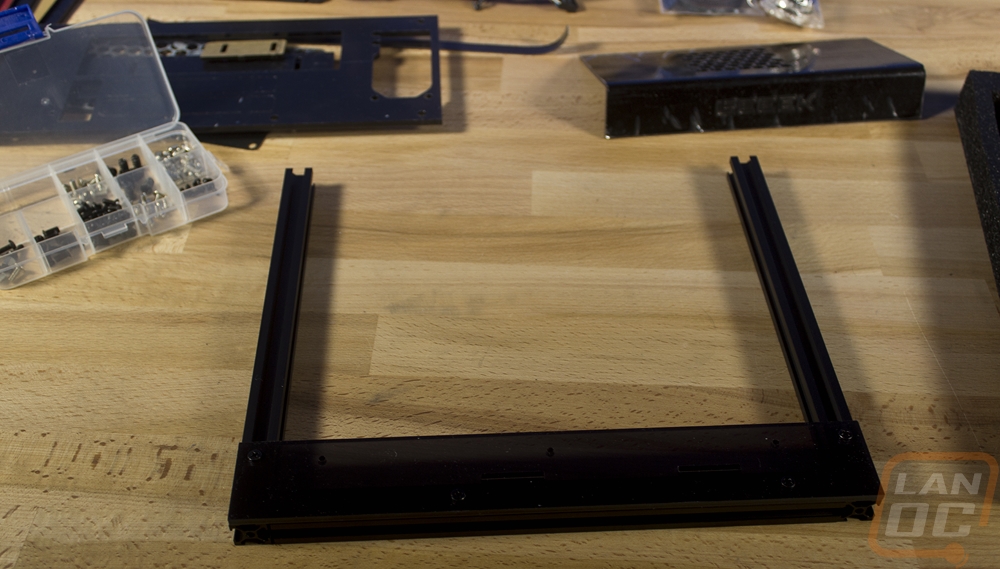

Then you work on the second half of the frame. It is three extrusions and just one small acrylic panel. Once together we just have to get one panel out to connect our original frame and this second half together. Once together it is almost looking like a case, well the frame of a case at least.

Next, you attach the four included feet to the bottom panel. Then you prep it with four screws and t-slot nuts and you slide it into place. Now we have the rear I/O area together and the bottom. This is the piece that finally holds everything together solidly. You can finally not worry about it snapping that rear panel in half if you bump something.

Next, they have you put the front I/O in. Much later in the build, I find out that I have the wrong standoffs here, they should be shorter and put the I/O up against that extrusion on the left so don’t worry too much if yours looks a little different. Getting these two screws in is a little tight. You have to go at an angle so be extra careful not to cross thread them.

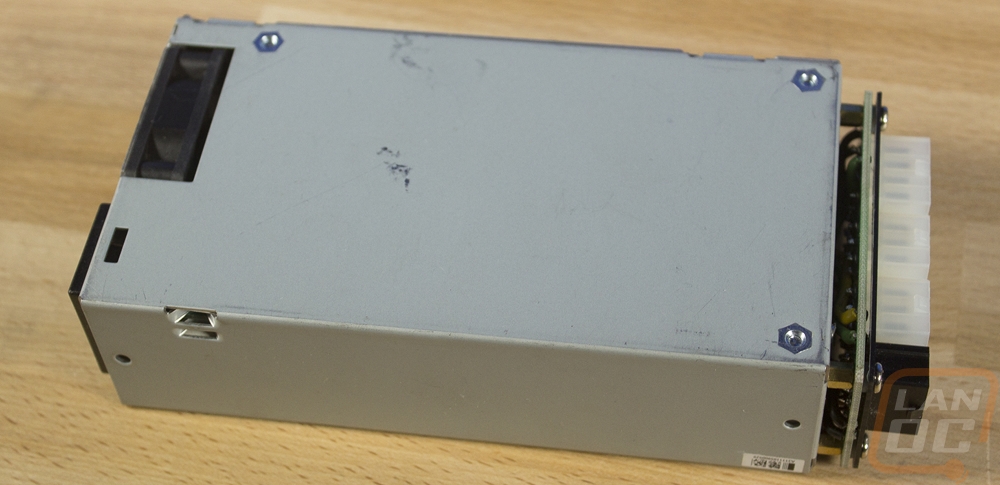

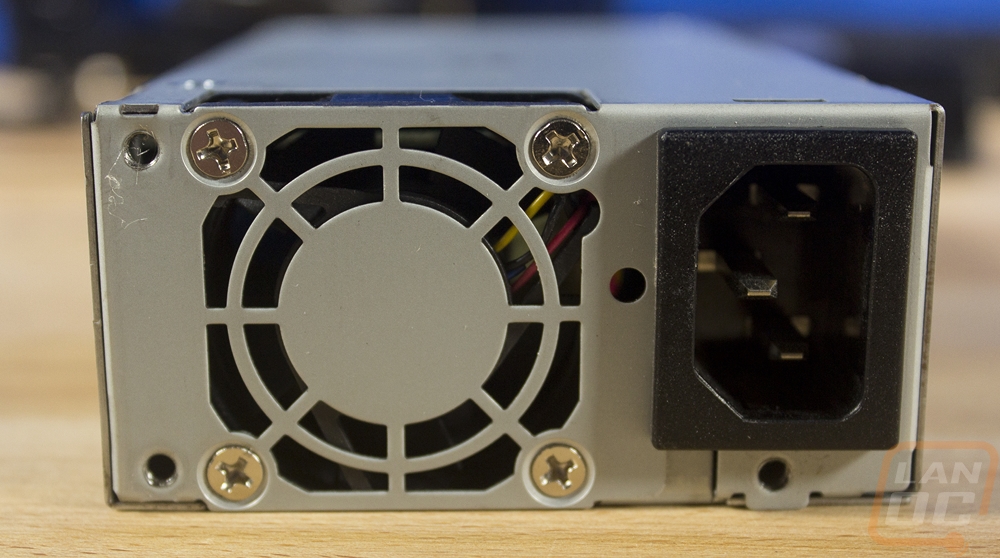

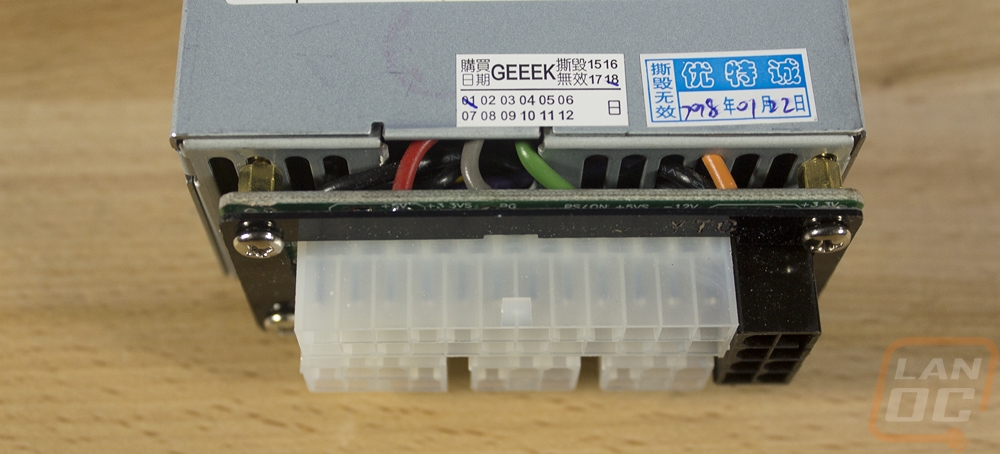

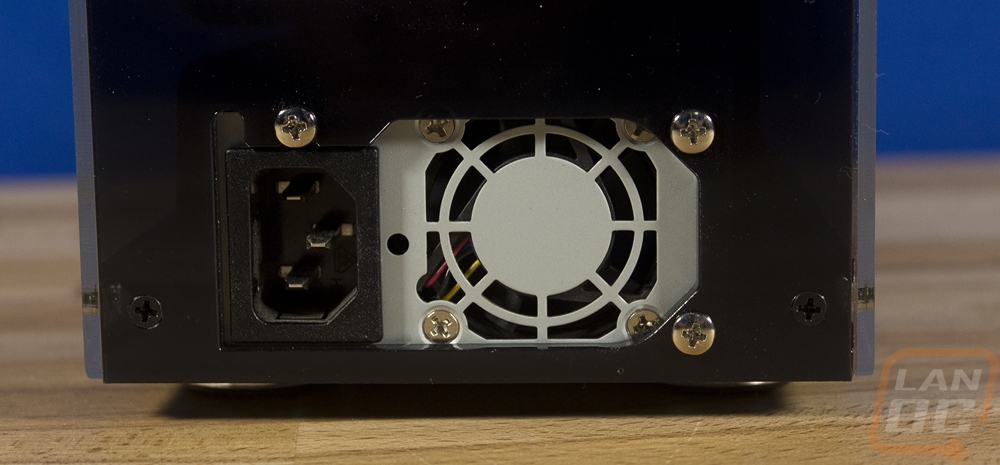

Next GEEEK wants you to get the power supply installed. When I first reached out to them about this case I came to the conclusion with my research that none of the Flex ATX power supplies on the market were going to work for me. Obviously, they had reached that point as well because they sell a modified FlexATX PSU as well. There are a few things, first, we need enough power to handle a decent PC. In addition to that, because of the size of the build, there isn’t room for a bunch of extra cables, and typically FlexATX power supplies are for server use and are very loud. So their modified version has the fan replaced with a quieter fan and modular custom length cables. You can even pick the cable color! So the PSU actually comes in its own box away from the case. It is wrapped up in foam and then all of the cables are in their own bag at the end of the box.

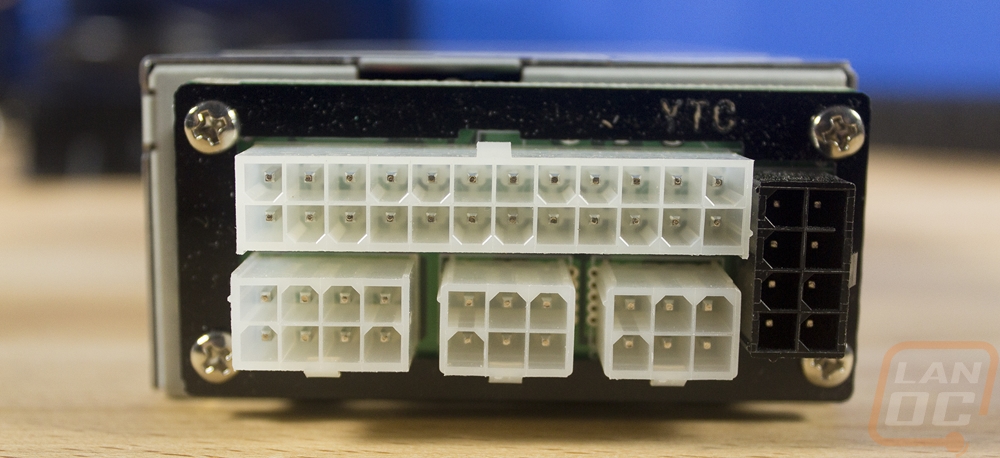

The PSU isn’t spectacular looking, it is your old school bare metal look. GEEEK mentions in their listing that they aren’t used, but you can expect a couple scuffs and ours did have that. No surprises though, this is a basic PSU that has been opened up. Scuffs are going to happen during that process. Anyhow if you haven’t seen a FlexATX before, they are a lot thinner but longer. You can see that the ends barely fit the fan and power plug on the one end, that’s also why noise is normally a big issue. You have such a small fan, so higher RPMs are needed. The modular end has a new PCB on the end with four connections. You have a 24 pin, an 8 pin CPU, one 8 pin for the PCIe cable, and then two connections for Molex and SATA cables. That’s all you get with SFX and all you need for any build this size really.

On the plus side of things, installing the power supply is extremely simple. Being modular meant I didn’t have to fight with any of the cables just yet. There isn’t a fan on the bottom so it drops right onto the bottom panel and fits snug between the extrusions so you just have to slide it back against the back and put in the screws. The power connector was tight but fit. I may want to pull it out later and paint the fan area so I don’t have to look at that grey/silver finish. To handle the rest I went with the optional PSU cover. I install that later, the instructions don’t actually mention when or how it is installed but I will talk about that later.

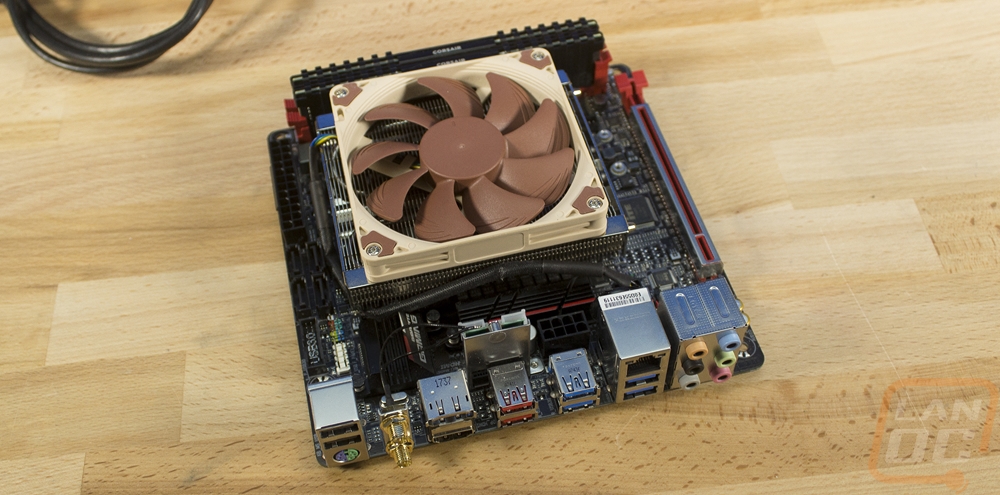

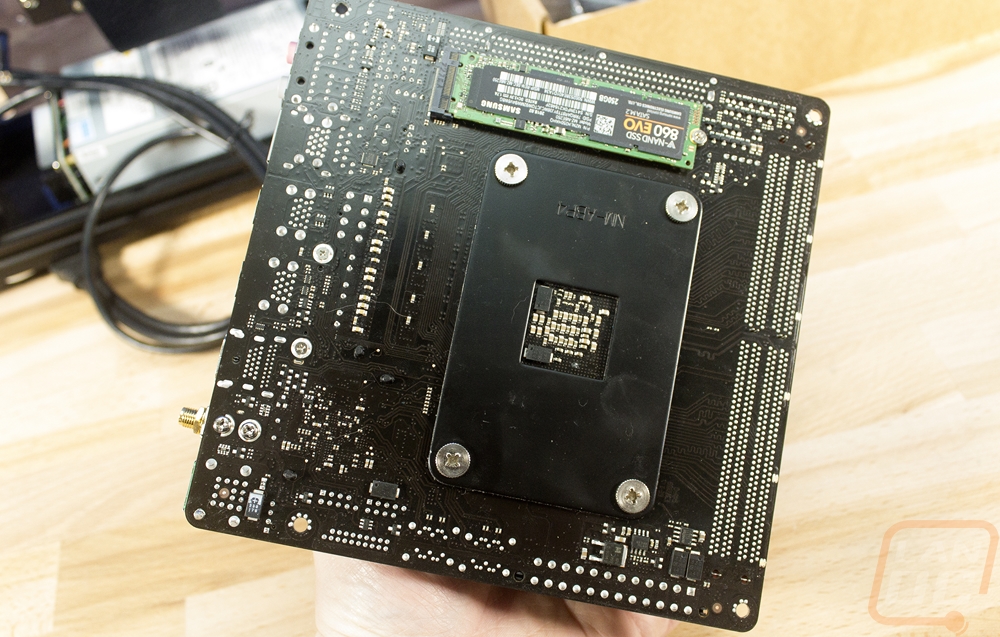

So the next step is getting the motherboard installed but before doing that I have to get it all prepped. That means getting the CPU installed, the heatsink, ram, and in our case the SSD as well because I went with an M.2 drive. I went with the Gigabyte AB350N Gaming because it has been our go-to ITX Ryzen board. I was originally planning on testing with an Intel CPU but frankly, the A30 doesn’t have a lot of heatsinks that fit. The overall clearance is 50mm so the Cryorig C7 is the obvious choice but I have ours currently being used in another build. It just so happened that Noctua sent a new NH-L9a-AM4 cooler and what a good place to test it out. So from there, I had to decide what CPU would best fit our situations. Obviously, heat is a big concern in small cases like this, but I want/need gaming performance so I went with the 1600X Ryzen 5 CPU, its 95-watt TDP just barely stays within the range of our cooler and 6 cores with a 4GHz turbo is a monster for an SFF build! For memory, I just went with the Corsair Vengeance kit that came with our original Ryzen launch because it was low profile and has great Ryzen support. Then for testing the SSD was just the 256GB Samsung. If I stick with the A30 in the future the 1TB WD Black might be calling its name.

So it's not mentioned in the instructions at all but I did find that the rear I/O panel did fit. It doesn’t fit snug but once the motherboard is installed it will hold it in place. A lot of these custom builds, or even a lot of the less custom cases from In Win don’t have I/O panel support so I was happy that it did work here.

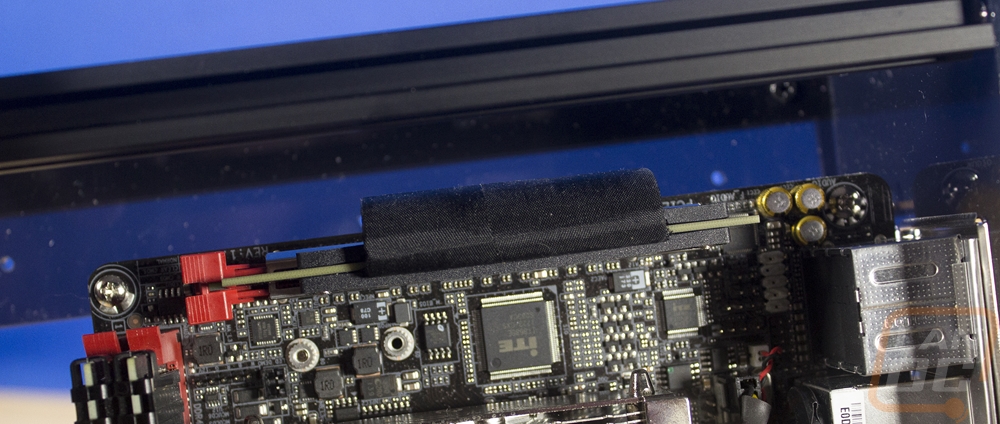

Getting the PCIe riser installed was really tight. As it turns out, I had mounted the bracket with the wrong standoffs so I think that made some of the difference. But even later with the correct standoffs, this is a tight fit. It is easier to install it into the board then to slide the board up and install it after. It looks great once installed though.

This is another step that isn’t mentioned at all in the instructions. But after looking ahead I found that getting the cables all installed and ran now was easier than waiting until after the video card was in or anything else. This was my first look at the cables that GEEEK provides and I love these. There isn’t any sleeving to stiffen or thicken things up. The cables are all black (but available in other colors) and thin and flexible. This is huge for an SFF build, most are a pain to work with. These are even a lot thinner and more flexible than the flat cables that some PSUs use for some cables. The silicon rubber used here is great.

Running the cables is going to be a challenge in any SFF case and this wasn’t much different. The main issue I ran into was because of the odd placement of the power connections on the Gigabyte board. I didn’t initially plan to use this board, had I known I would have asked for a longer 8-pin cable. So I had to dig out an extension cable (actually I stole it from one of our test benches, I’m going to hate myself later for that one) to hook that one up. Of course with all of that extra length now I had too much cord.

While doing all of this I figured I better get the PSU cover installed as well. I really wish they had instructions included. I just dropped it in place and it fits snug most of the time. There is a strip of magnet that I suspect is actually for installing this to the top of the PSU but because I wasn’t sure I didn’t use it. That said, it makes a huge difference in the look of this build. I would not go without it if you buy an A30.

Next, you have to get the whole top panel altogether and prepped. This includes installing the two optional 80mm fans. There are also optional fan filters, this is another one of those situations where I’m unsure if I have them installed correctly, basic instructions for the optional stuff would be awesome. The top panel sticks up a touch so I suspect that I need to pull this back apart and put it together correctly or I need to bevel the screw holes to get them to fit a little lower. I love the honeycomb grill though!

So for video card support, the A30 does have a limited amount of room. For starters, you only have 2 slots, not any extra room for the 2.5 slot cards. But that’s not much of an issue because you can really only fit the ITX length cards. GEEEK lists full-size GPU support but really they support 211mm normally and 228mm if you don’t use the front mounted 2.5 inch hard drive bracket. Well, I decided to use our Zotac GTX 1060 AMP! Edition, it is a little longer than the ITX form factor cards at 210mm but it should work. That said I don’t know how you fit anything longer, even without the bracket. I actually broke the shroud off of our card when trying to slip it into the A30. Once installed the slide down hold down bracket isn’t really ideal. I found that our card still moved around a little. I may actually replace it with a right-angled metal hold down that I could at least use two screws and bolts to lock the card from moving around.

With the video card installed I could finally install the top panel into the case. This is basically when we finally start to see the A30 close-up and become a real enclosure. It’s finally growing up! lol

Next, you work on the front panel, but before you do that you have to install the power switch. I also went ahead and ran the wire over and plugged it in. Then from there, you can install the case. This might be the easiest of all of the panels to install. There are six mounting points but only two of them use those hard to work with extrusion clamps. The top and bottom screws are all going into the ends of the extrusions. So I fought with the two middle screws first then popped the rest together.

Before buttoning up the side panels I did finally go back through the wiring to clean it up a little. With the Gigabyte board, my wiring is going to be a lot different than everyone elses, but I found that I could bundle up a lot of the wires going up to the top then to the left and it looked good. The USB 3.0 cable though was a big challenge to keep it looking good. Then when I got it looking nice it would push down on the PSU cover that I didn’t hold down and tilt it slightly. Going with the optional flexible USB 3.0 cable that they now have would make a big difference here. Plus it would match the PSU cables. Once everything is cleaned up, installing the side panels isn’t too bad. Unlike the other panels with the t-slot nuts, these are transparent panels. So you can see what you are doing and even if one slips out you can kind of finesse them back into place.

Photos and Features

Normally my case reviews would start with pictures of the case empty but really the GEEEK A30 requires a lot of construction after getting the hardware installed. I didn’t want to have to pull everything apart again to install everything. Plus these pictures look a lot better anyhow right? So the A30 is available in three color variations currently. You can get it in black, white, or a block/white combo. I went with the all black configuration. The pictures on their website with white in them look good, but I don’t know if those are all white or white/black combos, they don’t really show what the difference is between those two models right now.

Up on the top panel, the A30 has two 80mm exhaust fans with a honeycomb grill design to cover them up. The entire top panel and really the entire exterior of the A30 is in acrylic. The top, front, back, and bottom are all in black and the sides are transparent. The top and front have a dual layer design, I think this is where the white/black combo case comes in. But it looks good in black and still gives the case a little more style beyond just a black box.

The gloss black finish really stands out on the front of the A30. The six mounting screws are all visible but beyond that, you just have the front I/O and power button. For the front I/O you get two USB 3.0 plugs and then unmarked microphone and headphone jacks. The front power button is then just a standard vandal power switch with an LED ring. The LED lights up in blue but you could swap this out with any color to match your build if you want, or even with a different design with a dot LED in the center for example.

The GPU side of the A30, when filled up with a card like this Zotac, looks really good. They did a good job keeping the area under it covered and clear from stray wires to take away from the overall look from this side. Same up top, the smoked panel up there covers up any wires. In fact, combined with the black cables you can’t see any wiring at all back here (okay there is a touch of orange, but no one else is going to have use that extension cable like I did). Now I didn’t use any of the hard drive mounting, but there is an optional mount that replaces the video card with a 3.5-inch hard drive for those of you who don’t need the GPU POOwers but need storage. There are also two 2.5 inch drive mounts as well. So you could load the A30 up with an M.2 or two depending on your motherboard then an SSD and a hard drive in 2.5 or 3.5 depending on if you need the video card.

So the rear of the A30 really puts its overall size into perspective. The rear I/O for the motherboard takes up most of the space, especially when you combine the rear I/O of the video card as well. You can see that the FlexATX PSU down on the bottom doesn’t have much room between it and the motherboard. Leaving just a little room up top above everything for some wiring and the fans that we know are up there. You can kind of see how the video card isn’t sitting straight even with that top mount facing down. The PSU does need a black paint job though, that would help clean up the back of the case. Once in use, you will never see it though.

The bottom of the case is all acrylic as well but they did give us four large feet to keep everything from sliding off of a table. The mounting is a standard type so you could swap these out with other feet available from modding websites as well. They aren’t anything too special, but I love that they went with this style over a cheap rubber bump or something similar.

Performance

Okay, you might be asking what all can you even look at for performance on a case, especially one as small as the A30. Well, for the most part, a lot of my testing is normally focused on building in the case and how well some functionality works. In this case, I was curious how well it would work for LAN use, especially with an acrylic construction but beyond moving it around the house I haven’t had the chance to get it out to an event. I would be careful when transporting it though, acrylic can crack easily so any big bumps could have you needing a new panel or even worse. So if you plan on traveling with this I would wrap it up in a blanket in the car, if its cold at the event or if you are like me and your wife is always cold you will be set. If you take the A30 on a flight you might want to consider a much more robust way to protect it.

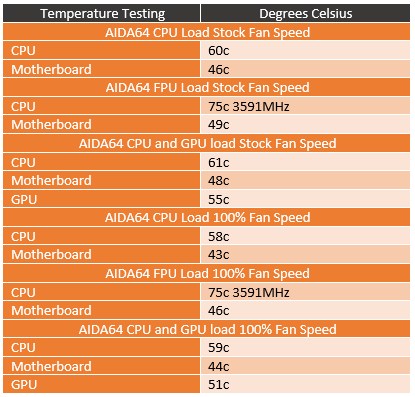

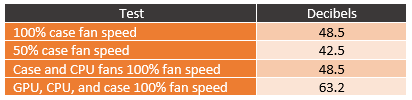

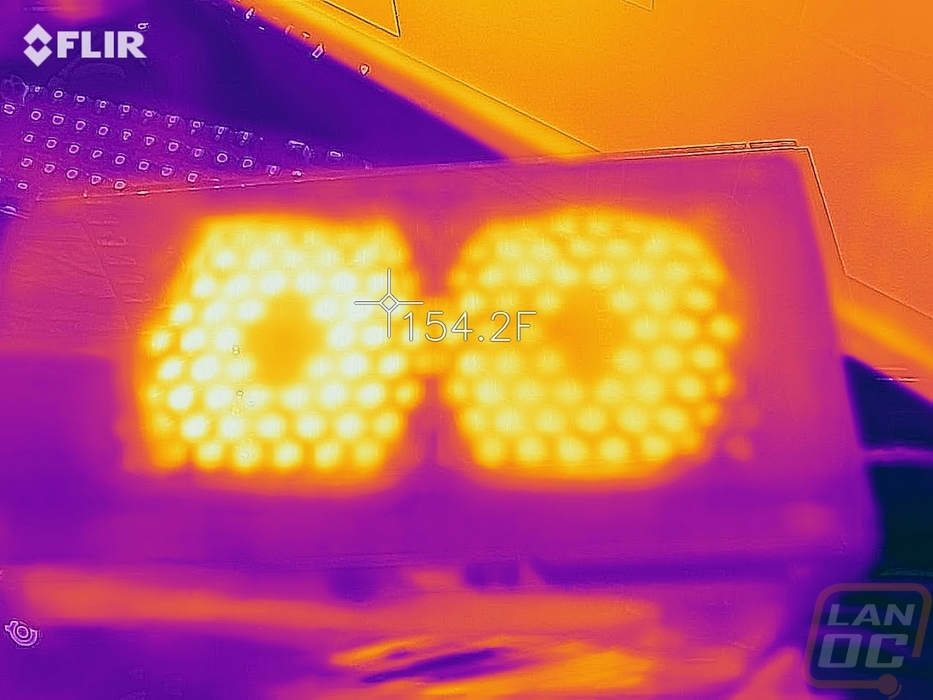

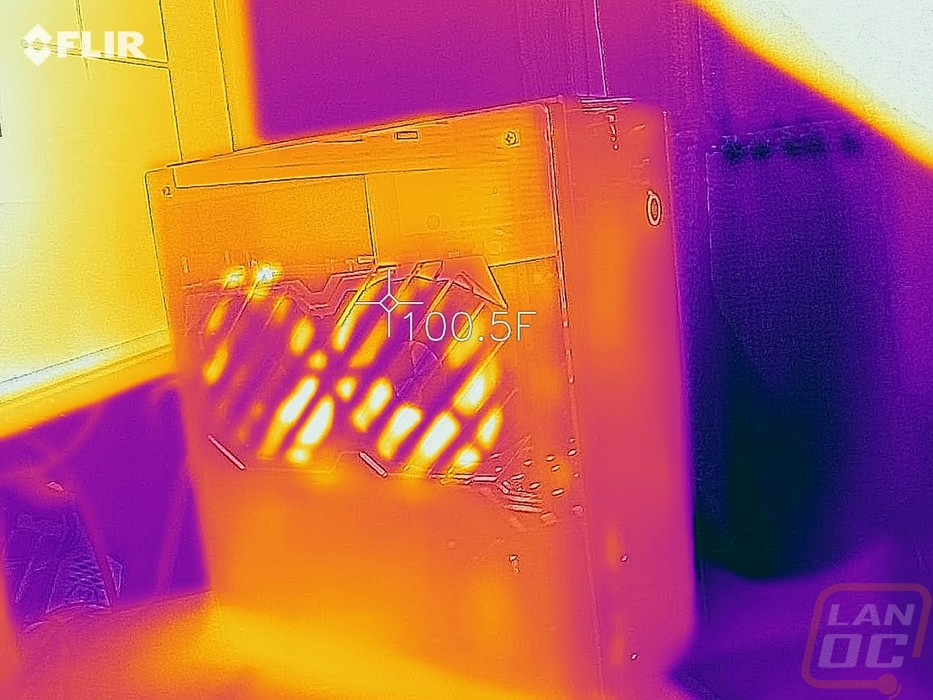

Beyond that, though I was especially curious at how well the two 80mm fans would handle the cooling of a 6 core PC with a dedicated GPU inside. In addition to that, I wanted to check out the noise levels of those fans.

For thermal testing, I ran a few different tests with different workloads. To start I tested with the fan speeds at stock settings and I ran the CPU workload in AID64 and then tracked the CPU Diode temperature as well as the motherboard temps. After a half hour what I ended up with was 60c on the CPU and 46c on the motherboard. That’s not too bad! The CPU load is as close to real-world usage as you can get, but I did also test with the FPU load that is extremely demanding. Here we did cap out to the 75c thermal limit and it dropped the clock speeds down slightly. The motherboard was warmer but at 49c, still not to bad. In other words, this was a limitation of the heatsink, not the case's cooling.

Both tests were done again with both the CPU and case fans cranked up. This did help with the motherboard temperatures overall and in the CPU workload test as well. The FPU workload was still maxed out though.

I did the CPU load combined with the GPU load on the GTX 1060 to get a full case load going. Here the CPU ran a touch warmer at 61c and 48c on the motherboard. The GPU ran nice and cool as it pulls in the cool air right through the side panel on both fans. In the 100% fan speed tests the CPU did run 1 degree higher than it did in the similarly done CPU test. The GPU was able to run a little cooler as well.

I also went in and got some thermal images of the A30 while doing the GPU and CPU workload. This gives you a better idea of how the case itself is handling the heat. I’ve had some SFF cases where because they are metal they start to absorb and radiate the heat from the CPU and GPU and that didn’t seem to be happening here with the acrylic shell. The intakes on the side panels show us the heat from the CPU and GPU behind them and the top shows how much heat the two 80mm fans were pulling out. The front fan did seem to be getting a little more heat, but nothing to be worried about.

Then my last test was noise testing. Really as far as the case is concerned the two case fan results are the only thing that is important. But I did do the other tests to put the noise in perspective. At 50% the two 80mm fans didn’t do nearly as bad as I had expected. I thought for sure I would need to replace these fans with something quieter later. They do make some noise but only really at 100% fan speed. Even then they weren’t nearly as loud as the GPU fans. That is basically where all of the noise came from in the build when using it.

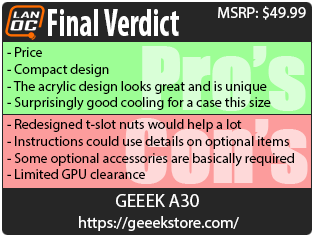

Overall and Final Verdict

Well building the GEEEK A30 and building in it has been an experience. There is no doubt that this is a lot different than just buying a case off the shelf, but is the extra time worth it? Well for starters, this is a great looking case when built. I love the all acrylic design, especially because its nothing like anything you will find mass produced. This looks and feels a lot more custom without being as high end and expensive as some of the community made cases. They also were able to do a similar riser based setup that puts the GPU on the back of the case for its own cooling without making the case too thick overall. The downside to that, of course, is you are limited to 50mm on the CPU heatsink and the GPU also needs to be a smaller ITX focused model. Thankfully Zotac has a bunch of options for high-end cards like that and the GTX 1060 had a lot of short options available from just about everyone as well. Combined with the improvements from the CPU races building a fast gaming PC with 6 cores in this form factor is finally easy to do.

Even with a 6 core CPU and the GTX 1060, I didn’t really run into heat issues. The CPU heatsink that I went with was the main limitation and there are a few better options with the 50mm limitation. Our Noctua is great but it is only 37mm, you really need to use every mm if you want any better cooling than this. More importantly, the acrylic design didn’t heat soak and the two 80mm fans pushed the heat out. The fans didn’t end up being as loud as I expected either.

Now one of the major downsides to this case is just how difficult it is to get together. It's not having to build it that is the issue, its smaller details like the t-slot nuts that they used. With aluminum extrusions being popular in 3d printers there are a lot of designs that they have used that might work better. The bonus is t-slot nuts that hold their place in the extrusion could also make upgrading in this PC a lot easier in the future as well. As it sits I’m dreading having to make a few fixes, let alone swapping out something like the heatsink where I would have to pull the entire motherboard out to do. The instructions weren’t bad at getting the basic case together, but I think they could be improved to show how some of the optional accessories install and maybe they should also include steps that show when to run wires and things like that. With how small the case is, you basically have to build the case alongside with the PC.

Speaking of the optional accessories, let's be honest a few of these might as well be requirements. Specifically the PSU cover, given there aren’t any good looking FlexATX PSUs, I think everyone is going to need that one. I also think right now the PSU they are offering is the only good one. Then there is the PCIe Riser, you could pick up your own but you do need to plan on picking one up. A quick look on Amazon shows that all of the 300mm risers are over $30 right now with a few of the nicer ones getting up into the 50/60 range. So the one GEEEK is selling might be a good idea.

Overall, even with the frustration with a few of the instructions and the t-slot nuts, I do love the A30. Its size allows you to pack in a monster PC into an 8.29-liter form factor. The pricing is especially attractive with the case selling for $49.99. Like I said before, there are a few components that you basically need to buy so that can add to the cost. The PSU and Riser are the two big ones, obviously, you would need a PSU anyhow but just to give everyone an idea of what you are looking at. The price as tested for the case, fans, fan filters, PSU cover, PSU, and PCIe riser is $165.78. Still well below the cost of a lot of the community made cases at this size and that includes the PSU with custom cables. Building SFF has never been all about the costs, it is always going to run you a little more. But when you get below 10 liters in size, I doubt you find too many options that are cheaper than this at least not with room for a GPU.