You know typically being based out of Ohio doesn’t have a lot of upsides. We are normally extremely far away from just about anyone in the industry. There is one exception to this though. You guys may have heard of a company by the name of Systemax, if not you have heard of one of their subsidiaries, Tiger Direct. Systemax’s Ohio factory literally is a giant facility in the middle of cornfields and small towns. I don’t think you could get a more stereotypical representation of what Ohio is to most people. That being said, I jumped at the chance to finally get a peek inside of this random factory that I had come across in the past out in the country.

You know typically being based out of Ohio doesn’t have a lot of upsides. We are normally extremely far away from just about anyone in the industry. There is one exception to this though. You guys may have heard of a company by the name of Systemax, if not you have heard of one of their subsidiaries, Tiger Direct. Systemax’s Ohio factory literally is a giant facility in the middle of cornfields and small towns. I don’t think you could get a more stereotypical representation of what Ohio is to most people. That being said, I jumped at the chance to finally get a peek inside of this random factory that I had come across in the past out in the country.

Systemax Factory Tour

Written by: Wes

Pictures by: Wes

My trip

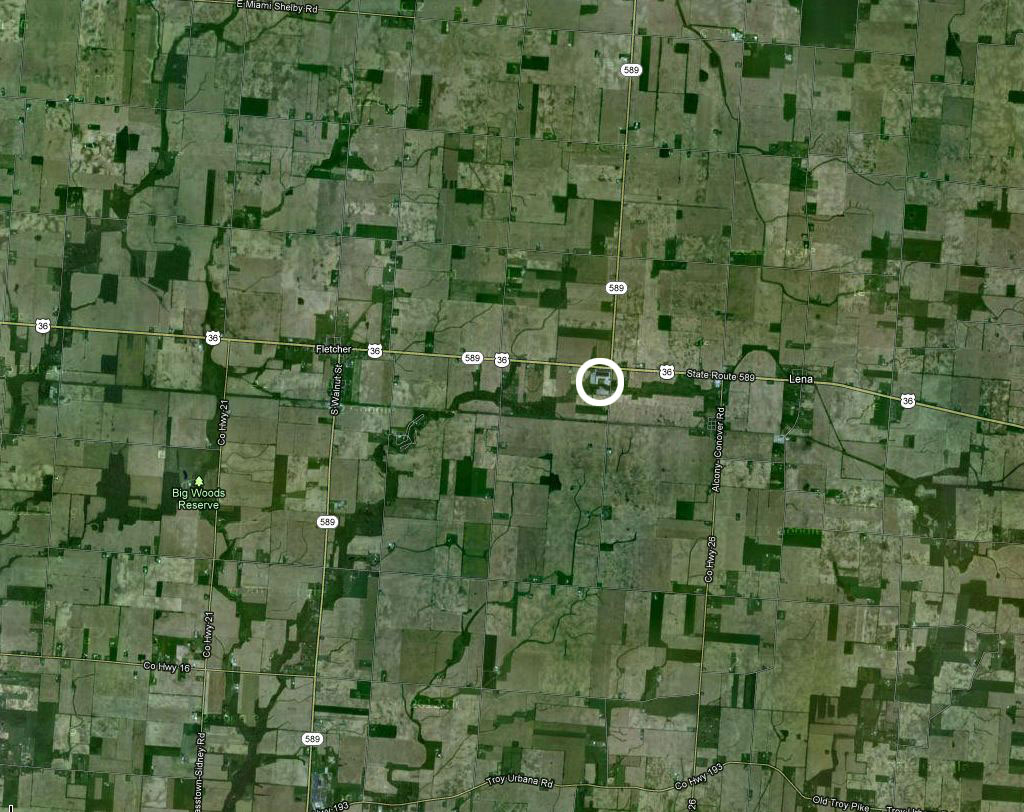

Typically I wouldn’t even talk about my trip to a factory, but considering the Systemax’s rural location it is worth mentioning. Technically their factory has a Fletcher, Ohio address but it is actually slightly east. To give you an idea of what we are talking about here. The Village of Fletcher has a whopping 474 people as of 2011. Yes that is the nearest place to go, and yes this is a village that is small enough that its Cemetery is 1/3 of the village size. The Systemax facility is actually nearly the same size of the Village of Fletcher when not counting the cemetery as well. Of course I joke about all of this, but I find this to be an interesting location that shows how Systemax handles things. See they were able to build a factory here in the US by keeping costs down and avoiding a large city. They are still close enough to the main interstate system as well as Dayton, Ohio and Columbus, Ohio to make them relevant. In a way this is genius, and this will actually reflect on a few observations that I saw while there as well.

All about Systemax

You would be forgiven if you hadn’t heard of the name Systemax up until now. They as a company have only been going by the name for 13 years. They were actually founded in 1949 under the name Global Equipment Company and they worked in the material handing industry. It wasn’t until 1981 that they start dealing with computer equipment. In 1995 they changed names again and went to Global Directmail and also purchased Tiger Direct at that time. Later on in 1999 they finally switched to the name we now know Systemax. In 1997 they picked up Midwest Micro and Infotel, this included the factory that we took a tour of as well. A year later they went on a spending spree in 2008 and then 2009, picking up CompUSA and later Circuit City brands. That’s right, Systemax is Tiger Direct, CompuUSA, and Circuit City. This is actually a very short version of the relevant history of the company. You can find a more in-depth timeline HERE.

Systemax is a continually growing corporation with over 5000 employees and total sales over 3.5 billion in 2011 alone! Take a look at their sales over the past 10 years. You can see that they continue to grow every single year.

Offices

Going into the offices and having been in offices from a lot of other companies I was impressed with the amount of space that Systemax has to work with. Once you get your visitors pass and get past the doorway their waiting area is just gigantic, and even with a couple couches it felt a little empty. Here I realized that unlike other company’s based out of LA or other expensive cities. Being out in the country affords Systemax with a much lower cost per square foot and it shows. Area’s like their break area’s are much larger and I even saw a room with air hockey, multiple dart boards on the wall, and even a large full wall projector with a Wii hooked up. See in the past what is now the office was most likely both the office AND the manufacturing area. With a few additions to the facility it left the office with lots of room.

I had a chance to stop and talk with their tech support. Not only were they very nice but I was given the run down on how having on site tech support helps them. Their tech support lead works very closely with their engineers and product managers to give quick resolution to issues that come up as well as giving them the ability to setup an exact duplicate of the customer’s setup to try to replicate issues when they arise. They estimated that they support around a million PCs currently but I will be honest the phones were very quiet in the time that I was there. This is very impressive considering the number of PCs that are supported and is a perfect example of how having a quality product being shipped can save time and money for both the customer and the company in the end.

They do both online and over the phone technical support through their website http://www.supportforyourpc.com/. Over the phone their staff stays on duty for 18 hours of the day due to the lack of any calls in that short overnight period. This isn't a shock to me considering how busy they were in the time that I was there. What is impressive is that they are providing full support right here in the states. Anyone who has been on the phone with someone who they had trouble being able to even communicate their issue to will respect that their support is all US based. In fact to give you an idea, right next to their support section was their sales offices and being in Ohio I saw lots of people sporting their Ohio State colors.

Factory

First things first, before even thinking about getting in or out of the factory you have to go through security and a metal detector. This is similar to what we have seen in other factory’s, but a step above what we have seen at boutique builders. This was my second clue that Systemax isn't a boutique builder; the first clue was the size of the factor itself. Once in, I found that the factory is split up into a few building areas, each fully capable of running an entire production line of different PC’s at the same time. Because of that some of my photos are going to look a little redundant.

I first want to point out that everything about the factory is top notch and designed specifically to try to prevent static discharge as well as damage to any of the equipment. That means everything is temperature controlled and as you can see, even the mats that each person works on are grounded out.

Each product line has a roller assembly line where things can be pushed down to the next person. We got into the factory fairly late in the day meaning most of the production had already moved from building to installing and testing. But I did still get an idea of how their production goes. First every build starts out with a tray designed to roll on the lines correctly. Where I found these to be especially interesting is how they are designed to hold all of the parts needed for the build and then later they will hold the build as well. Each tray has spots on the right side for any of the systems hard drives to be secured as well.

The trays are filled on a roller line that goes past a wall of hard drives, cpu’s, ram, and anything else you might need to build their PCs. The tray along with a printed list of the PC included all of the parts moves along being filled up and ready to go.

There is another variation on this that also uses a much simpler tray design. When building their pre-built systems. All of the parts are still on pallets right next to the production line and each system is built in that way. There isn’t a need for the picking system of the other lines simply because every system is going to be the same in these production runs.

Unlike most other manufactures, every single PC that comes through the Systemax production line is run through a full burn in. This reminds me a lot of how Kingston’s factory was handled. Both companies spoke about how it is much cheaper to spend the extra time and money now to make sure everything works rather than spend all of the money later in shipping, replacement parts, tech support man hours, and most importantly the customers time. Because of this every production line has whole sections dedicated to burning in and setting up the machines they build.

One other area that I had a chance to take a look at was their RMA area. Anytime a PC comes requiring repair they bring it in and test and confirm what part is bad. If it is a pre-built system they will typically have another ready to send right out to the customer. From there they take the good parts out of the systems and store them in a fenced in area to build other refurbished systems. These parts are kept in this specific area to prevent any of them from slipping into regular production, it’s a small touch but it is nice to see that they have considered this possibility. As you can see, the RMA area was really quiet while I was there, the only system sitting around was actually the build that Systemax used at Quakecon.

Here are a few other pictures from around the factory that I thought everyone would find interesting.

Engineering

Of all of the area’s I visited their Engineering was by far the smallest. Yet I still spent the most time there. I spoke with one of their engineers for the better part of my visit talking about both how they come up with their different products as well as how they test and burn in every PC that they sell. I touched on this a little in the factory section of our tour, but here they actually went through their entire process of setting up, configuring, and later burning in each pc. I was very impressed with how they go about all of this and at the same time very jealous. Their entire installation process is run off of the various SKU’s that each part has. When doing the initial install it picks up what parts make the build and the full installation is customized to that build.

The process starts out by booting up the PC and updating to a validated version of the motherboards firmware. While in there the engineers can actually tag if any other settings need to be changed in the BIOS to customize for water cooling for example. Once the firmware is updated, the process starts the windows installation while also including all of the driver’s for each part of the PC build that have been validated. What they mean by validated means they may not install the most current driver, rather they install the most current driver that they have tested and confirmed that it doesn't cause additional problems.

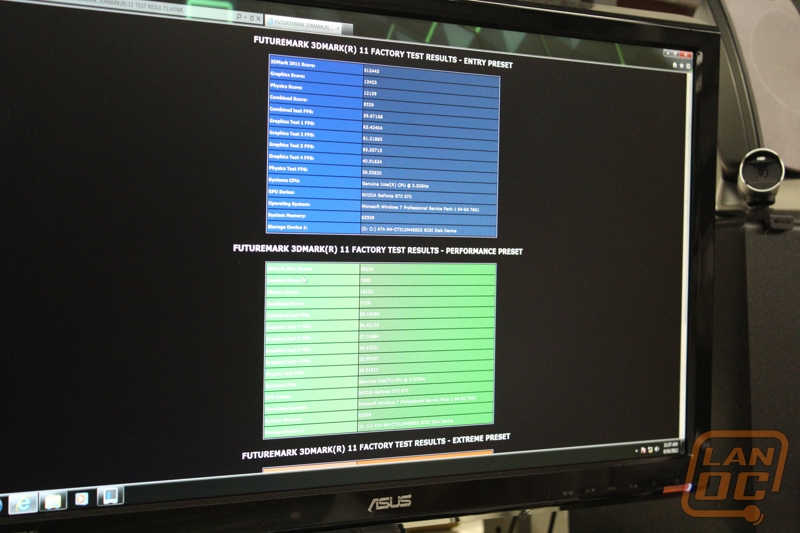

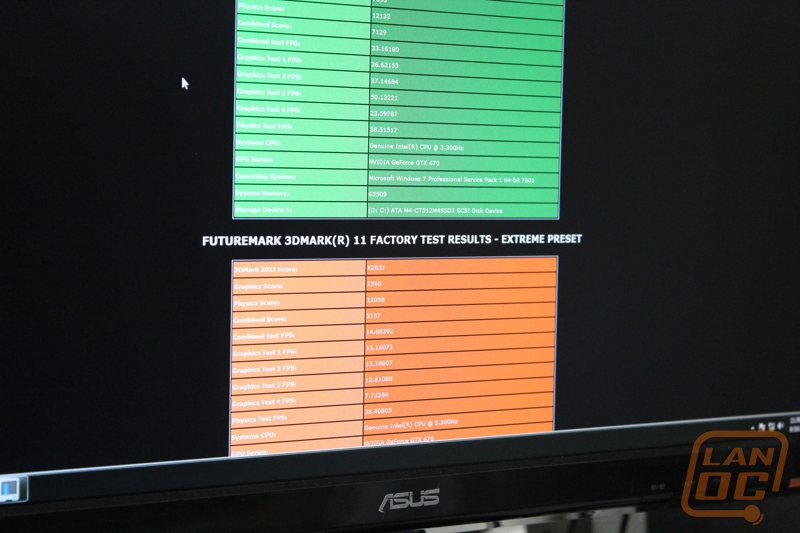

I even got let in on a little secret. Every PC that ships actually has the logs and results from all of the tests run it before it is shipped to it new owner. That means that those who buy a SYX gaming PC can actually find its 3DMark results for example. In fact with 3DMark they actually put all three (entry, performance, extreme) on one html page for easy reading. The results aren't on the desktop or anyplace that easy to find. But they are in the logs folder on the backup partition.

Although I spent almost all of my time in the engineering section that focuses on gaming, there are also server, notebook, and normal pc sections as well. All of the same level of testing and retesting applies, just without the same cool hardware that we all know and love.

Warehouse

At the far back of the facility is by far the largest of all of the buildings. It’s clear right away where we are though, this is the warehouse. Most people wouldn’t get too excited but for me, I was really curious to see what kind of hardware they keep on hand. Frankly I was a little shocked at the size of the warehouse, but they do have a lot of product going through. The warehouse is split up in to three areas. The area you walk into first runs the length of the building and is where all of the semi bays are. Although I got to this area well after the factory closed down for the day they did still have a few people here up and running. I’m sure that it gets much crazier in the time before UPS and FedEX show up as well. The second section is where everything is stored. I tried to get a picture to capture the size and amount of the bins, but frankly no one picture could fit it all in.

There are around 12 complete rows of bins along with a long bin that actually helps device this area from the bay area. Each bin is floor to ceiling for the most part allowing them to fit four full height pallets. Then each row is extremely long as well. On top of that important or high volume items are also stacked on the end of some isles for quicker access.

As you can imagine, their warehouse was packed full of both fully built systems as well as the parts that are needed to build them. I saw pallets and pallets of the new Bit Fenix Prodigy, Corsair’s new Vengeance C70 gaming case, and literally over an entire row top to bottom of the Cooler Master HAF 912 that they use for a lot of their builds.

The third and final are of the warehouse that we took a look at was their recycling area. Spending a little time in this area was actually depressing for me, but still a great representation of how the company operates. Systemax recycles anything and everything that they could possibly recycle both from the factory and their offices. That means we saw pallets of soda and pop bottles as well as paper. Then where I really was heartbroken, we also was pallets of motherboard, PSU’s, cases, add in cards/gpu’s, ect. It’s great to see that they are handling these things correctly, but it was still hard not to want to cover my walls in motherboards when standing next to them all.