Performance

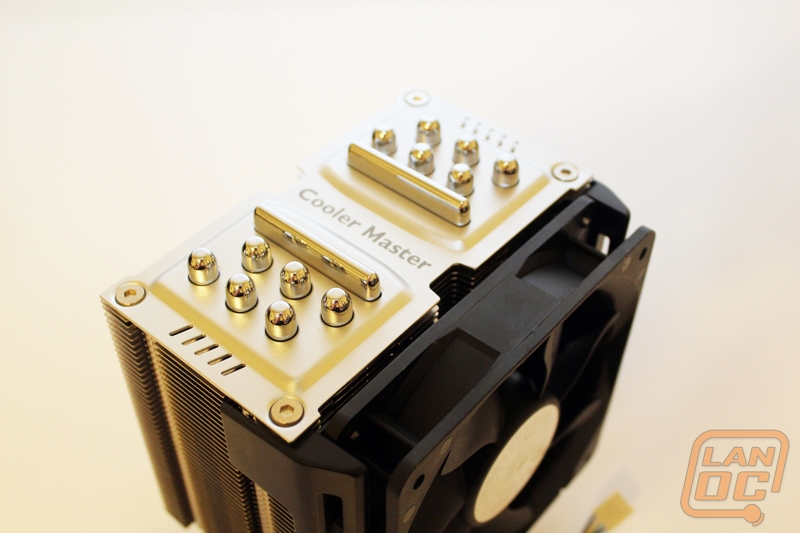

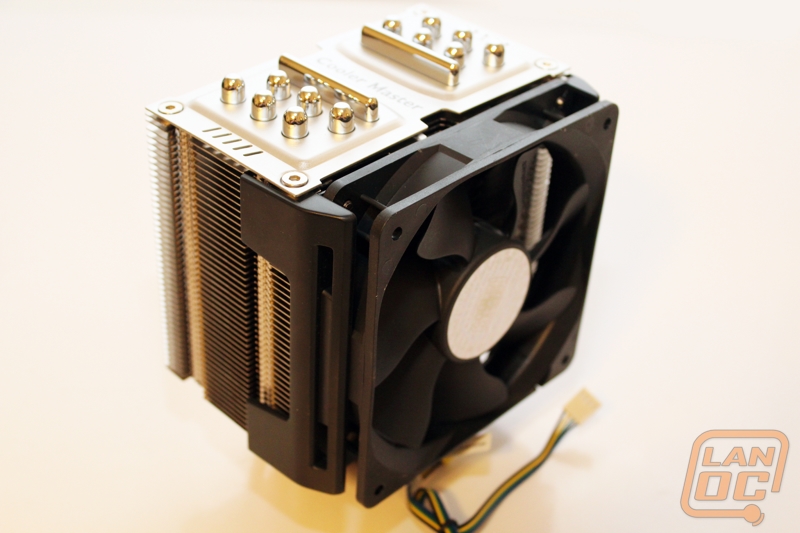

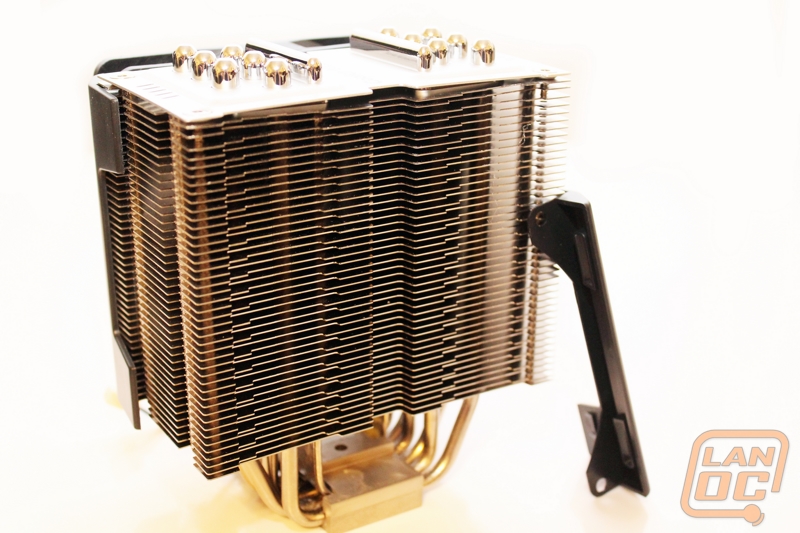

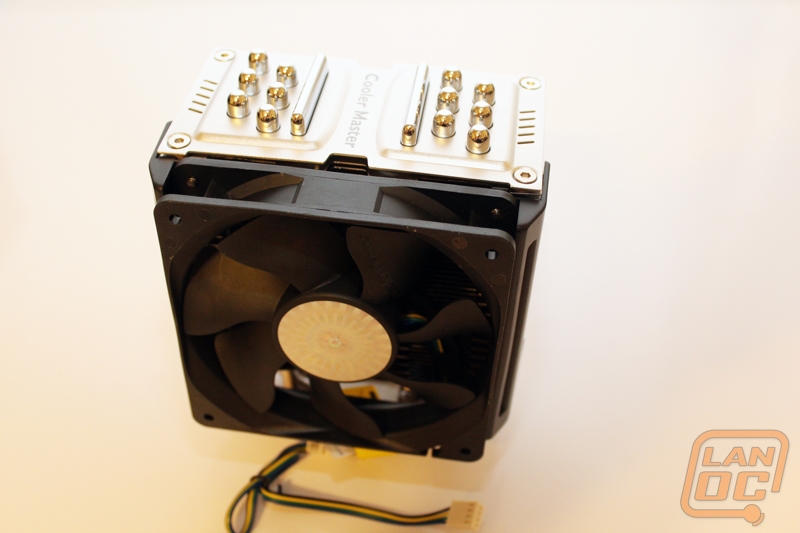

Take note first of the top of the cooler, for a few reasons, the first of which is that once installed, you’re not going to have a choice but to look at it. Admittedly, it is a nice finish. Though the heat pipes protrude and gloss, the base of the top is a satin metal, subtlety branded in a soft font. Let’s compare this again to the Hyper 612, which had a plastic cap and aluminum heat pipes. Cosmetically speaking, the TPC 812 will probably fit in easier with the rest of your build. Silver and black are more universal than forcing warm hues such as copper.

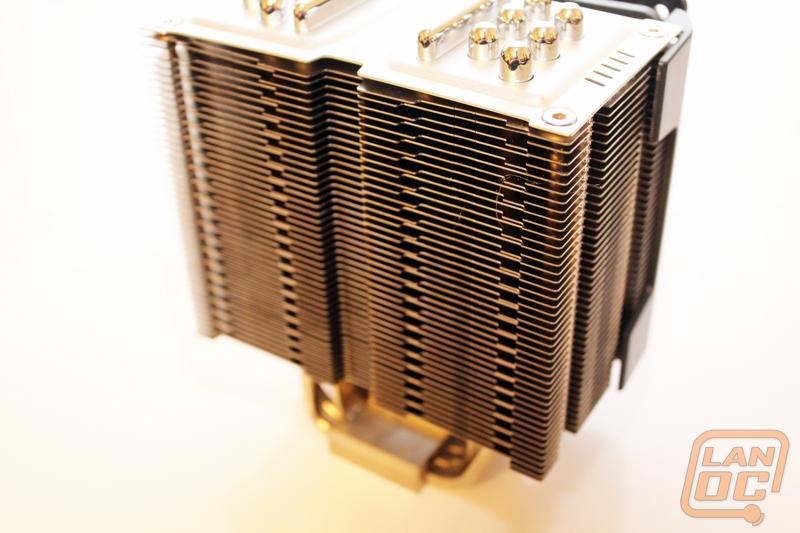

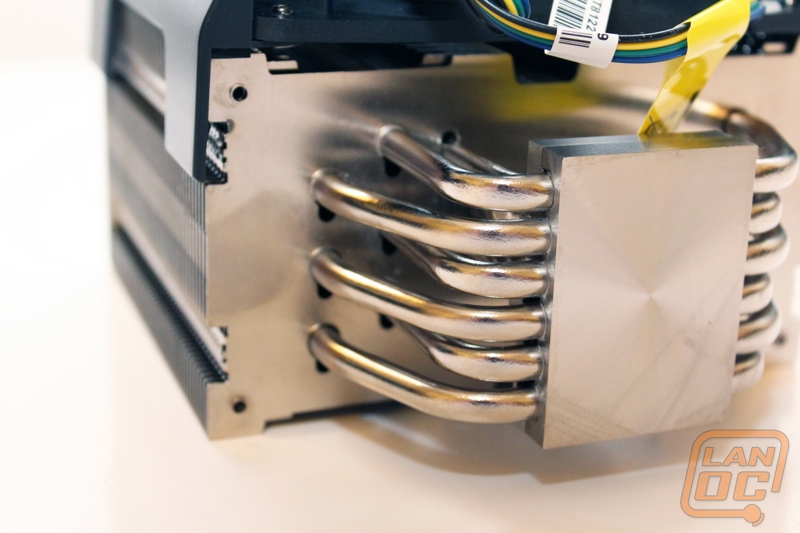

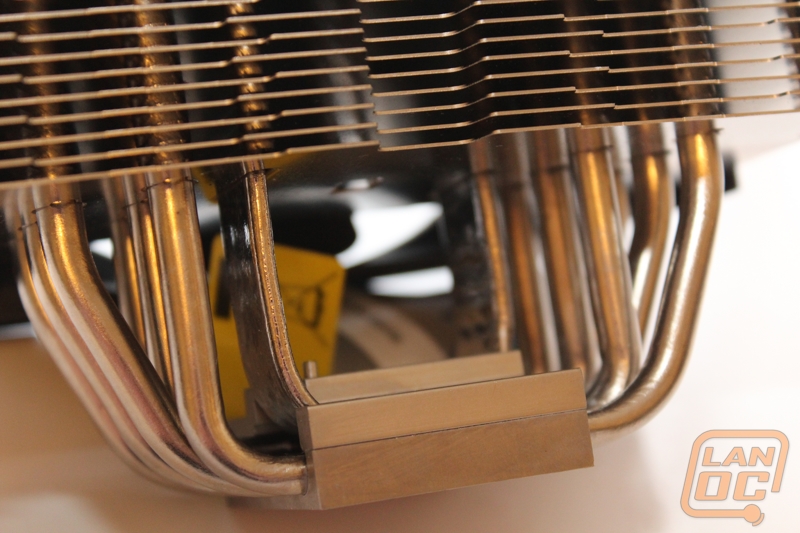

You should also notice a difference in heat pipe design, even shape for that matter. The TPC 812 includes six heat pipes on each side of the fins, but also features an elongated pipe the width of three pipes combined.

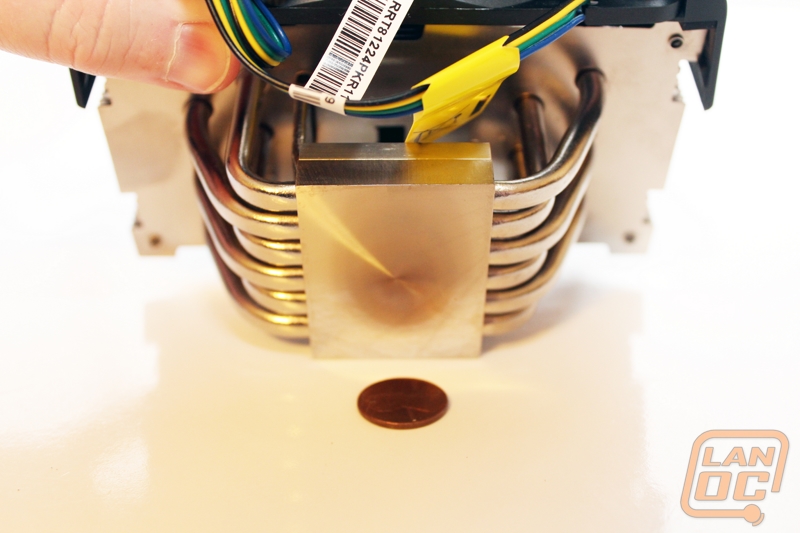

The base of the cooler helps to explain what and why. Between the heat pipes, which meet together on a square platter that rests on the processor as usual, you’ll notice a second layer, which this flat pipe terminates to. Essentially, Cooler Master is maximizing the surface area available to add another avenue of heat transfer, officially dubbed ‘vertical vapor chambers’. It works in the same manner of traditional heat pipes, trading the heat as it travels up towards the fins and evaporating back down to begin the cycle again.

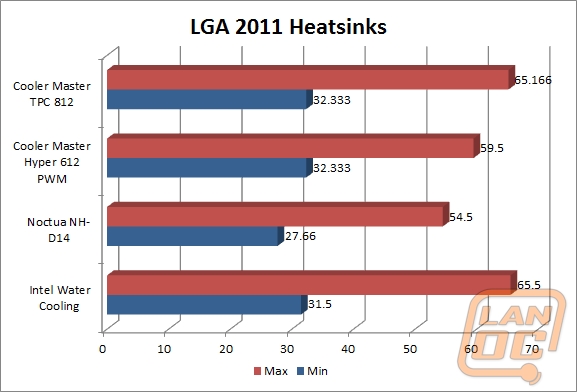

How do these vertical vapor chambers translate in testing?

The addition vertical vapor chambers weren’t enough to compare to the 612 PWM’s extremely large surface area. Take that trade off as you will: if size restriction comes into play, the TPC 812 is still a great option, especially considering its on par Intel’s stock water cooling. We were surprised to see a difference between the coolers, to the point where we ran the test several times, on the exact same set-up and ensuring the same ambient temperature. What we determined was that although they used a more efficient design, it still wasn’t able to overcome the difference in overall size and surface area between the two heatsinks.