Performance

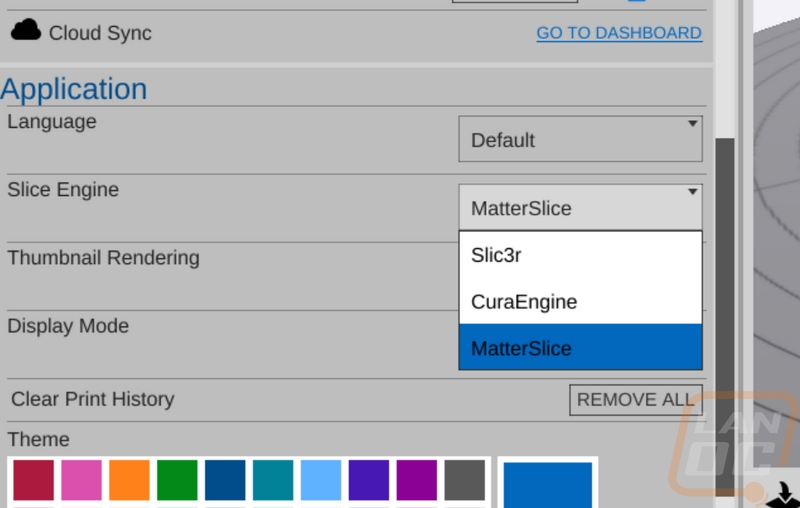

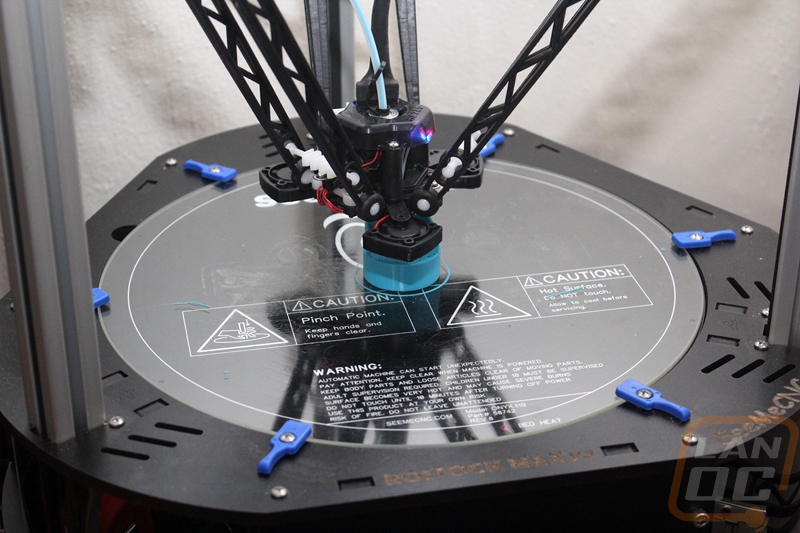

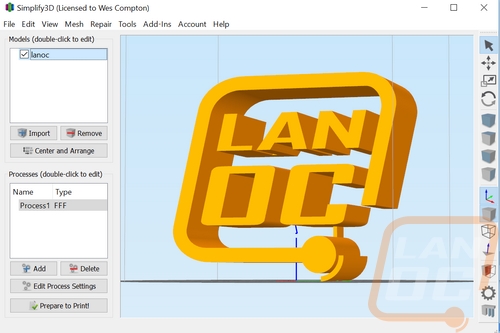

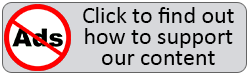

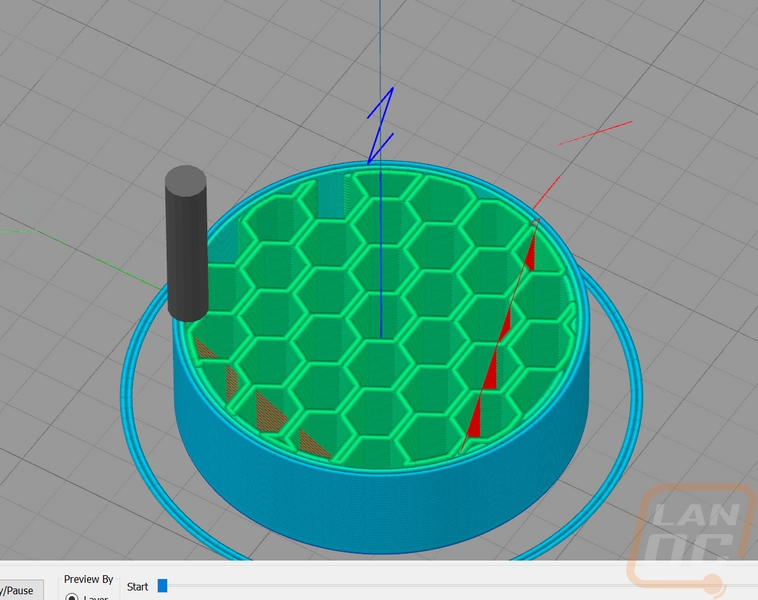

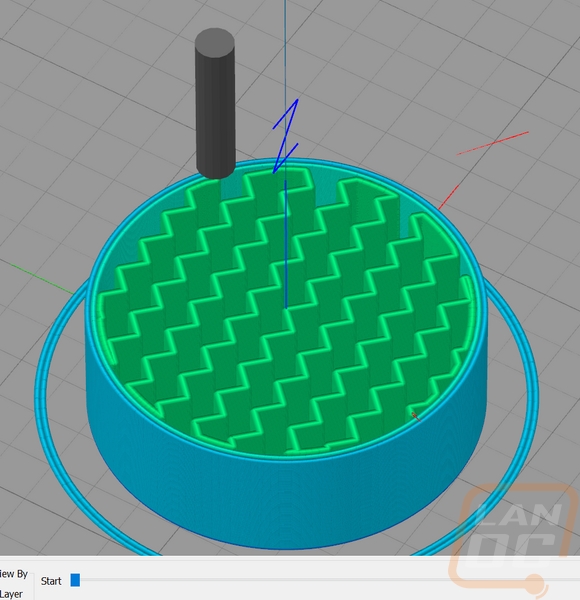

So now that we have everything setup and we have run through some of Simplify3D’s key features I started in on my actual testing. Now keep in mind I did a lot of this over a few months, but after I finished up my review of the SeeMeCNC Rostock MAX v3 last week I jumped straight into a few final tests. The first thing I wanted to talk about was infill. Both Simplify3D and MatterControl have a drop down menu of different infill patterns you can use, but I was surprised by a few of the options. In the past, I have stuck with triangular infill on just about everything I have printed with the exception of a few of the transparent prints where I toyed with honeycomb because of its aesthetics. Well with Simplify3D I was really impressed with their fast honeycomb that actually prints half of the honeycomb in one direction on one layer and then the other half on the next layer. This gives it good strength but saves print time and a lot of material as well. There is actually the option to set the number of layers skipped between infill layers on all of the types, so you can toy with it to save material. Then on top of the standard lines, squares, triangles, and honeycomb infills that both programs had Simplify3D had a weird zig-zag line infill and MatterControl had a weird cylindrical infill. Both designs don’t seem like they would do a very good job of supporting from every directly.

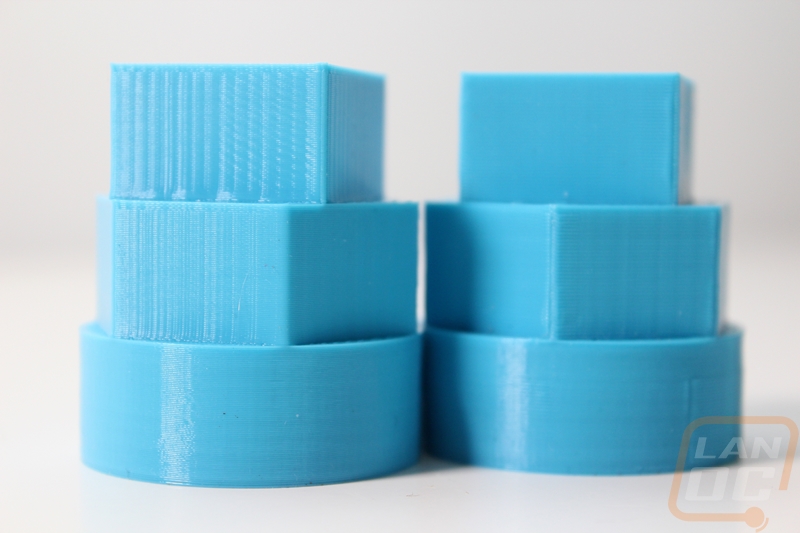

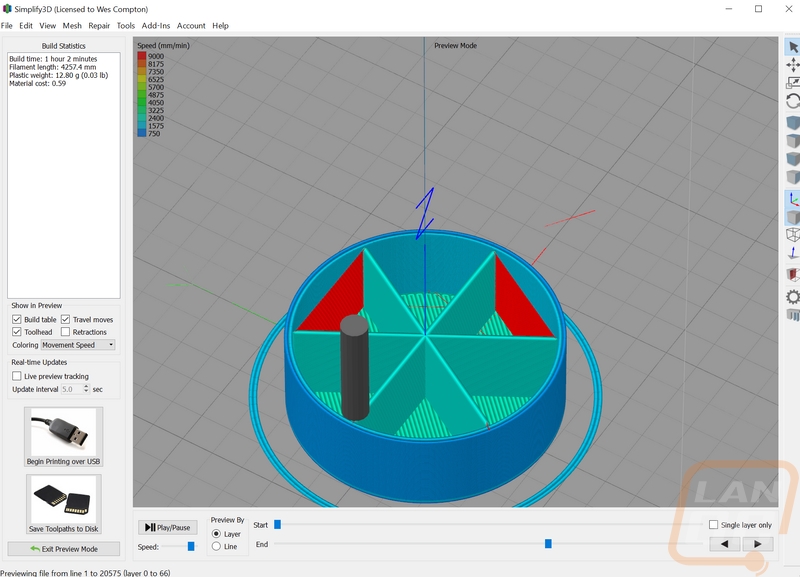

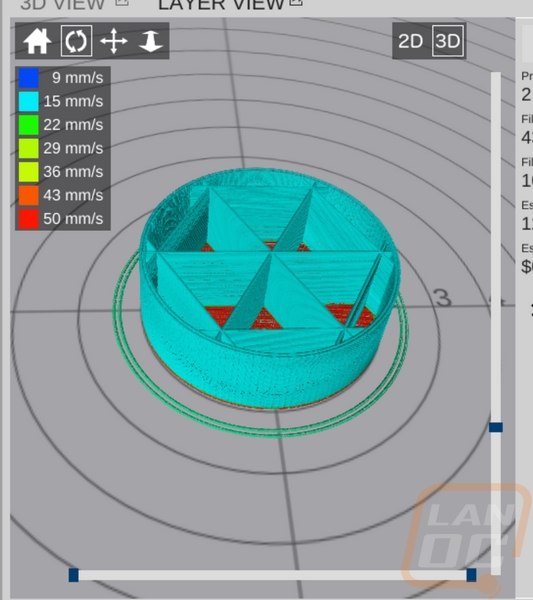

When doing my testing I noticed another weird thing with the infill as well that I felt important to point out for anyone switching from MatterControl to Simplify3D or the other way around. When setting my triangle infill to 10% like I prefer I noticed that the two programs had two different ideas of 10%. You can see from the image below, the 10% on MatterControl (second picture) has more support than Simplify3D, so make sure you are getting what you had planned.

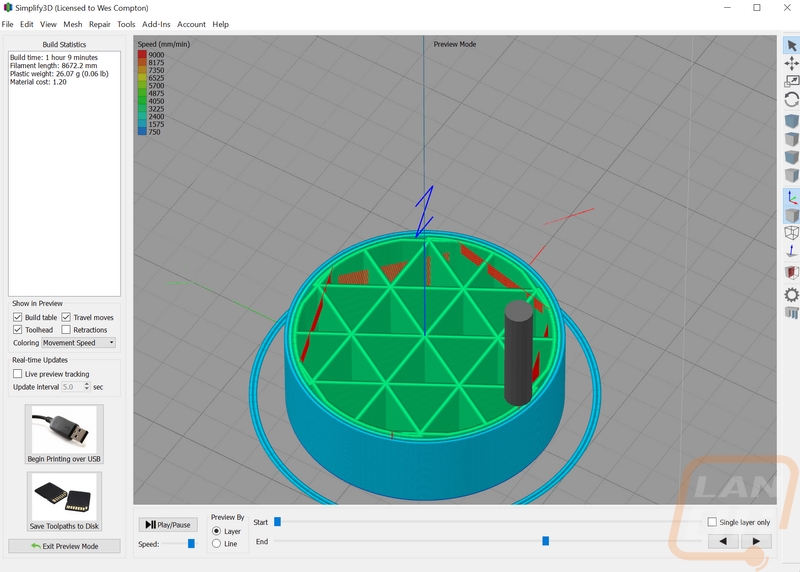

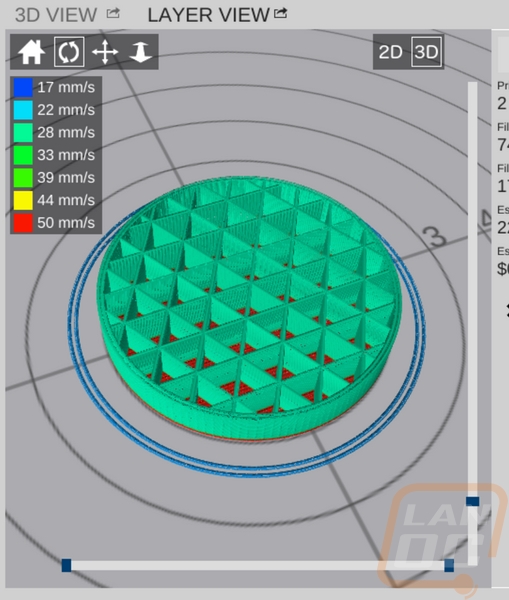

Here is 30% infill on both as well (Simplify3D first, MatterControl is the second image)

Of course, infill is only a fraction of the software. What stood out to me the most with Simplify3D was just how quick and responsive it is. Loading models were almost instant but I was most impressed when it renders all of the supports and creates the g-code to print. In MatterControl, especially recently big files would sometimes take so long that I would tab out and wait or it would even sometimes just crash. Simplify3D, on the other hand, is instant all of the time, it’s like a completely different PC when working with it. Simplify3D also seems to be closer to its estimated print times as well, making it easier to plan around prints.

That said when going to print from USB I did notice it takes longer for Simplify3D to get my printer heated up. MatterControl will start heating up both the extruder and the heatbed but the default setting (at least for the Rostock MAX v3) is to heat each up individually.

One of the big things I mentioned in my Rostock MAX v3 review was the vertical banding I see on prints with the delta printer. Part of the issue is the controller, but I also know that depending on what slicer you go with you will see different results as well. With MatterControl you can pick from a drop down list of slicers but I normally would use MatterSlice because it performed best for me. With Simplify3D they use their own slicer and I had heard good things about its print quality so I setup a print test to see how they compared with the vertical banding in mind. I printed the “Bandaid” print that is shared on the SeeMeCNC forums for slicer testing and here are the results. The model on the left is MatterControl and on the right is Simplify3D. Now the new slicer wasn’t the end all be all, I do still have banding but there is a noticeable difference with both running at the same print speeds on the same model.